5 Reasons You Need a Heavy-Duty Power Tugger

Power Tuggers

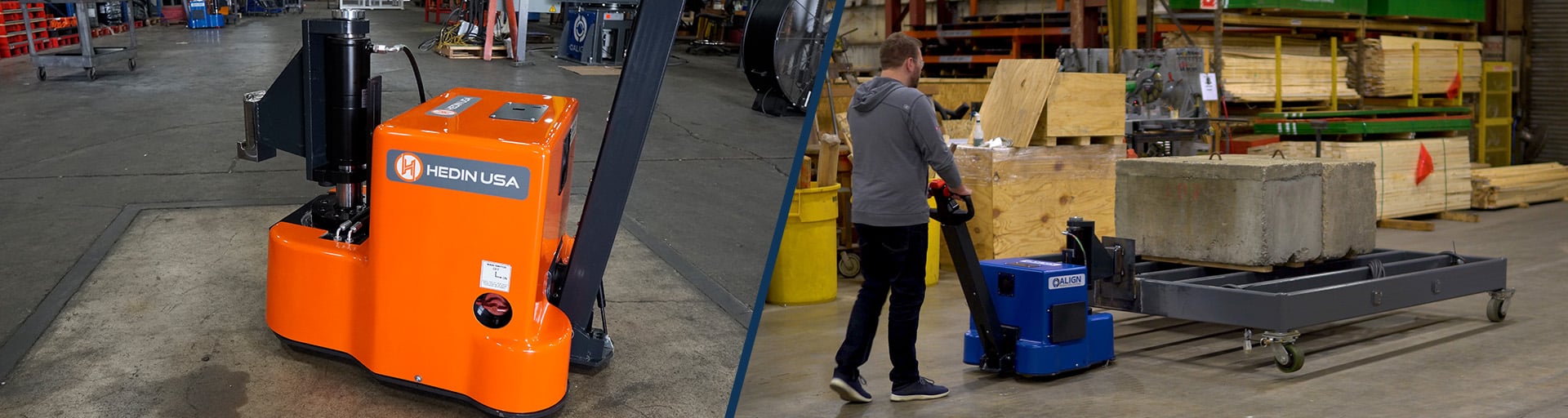

Power tuggers are walk-behind battery-operated units used for material handling in various industries moving loads up to 80,000 pounds. When you’re moving large loads in a manufacturing facility, and you need a single-operator solution, a heavy-duty power tugger is the ideal choice. Here are the top five reasons why every facility should consider investing in a power tugger:

Conclusion

Power tuggers offer an unbeatable combination of safety, efficiency, and ease of use, making them essential for any facility handling heavy loads. They are customizable with various hitch options to meet specific needs, further enhancing their adaptability across different applications. Whether for pushing, pulling, or navigating confined spaces, power tuggers are a must-have solution for improving operational productivity and safety.